As the cost of energy and water continues to spiral upwards, architects, builders, planners and environmentalists are constantly on the look out for new technologies that can optimize the operation of cooling equipment. Selecting the right chiller controllers is a good first step.

One of the greatest users of water and energy are building air-conditioning systems and industrial process cooling systems. For this equipment to operate at peak efficiency, it needs to be monitored constantly. This is now possible with our programmable Chiller Controllers and System Remote Masters.

It is no secret that chillers require a significant amount of energy to operate. A great deal of time and effort has been spent on reducing these energy requirements. Over the years, in fact, the average performance of chiller systems has been improved, and the efficiency of the compressors and the heat exchangers increased. But even further gains are possible through the optimization of the management of the units and systems. This is where our chillers leave the competition behind.

Our new line of chillers can be remotely controlled from the comfort of your office. With these programmable chiller controllers, you can control up to 12 scroll compressor chillers by staging of the 24 compressors, making them operate at the highest efficiency as possible. Not only can you optimize the cooling capacity so that it matches your cooling load at all times, these controllers can make diagnostics a breeze and repairs much faster.

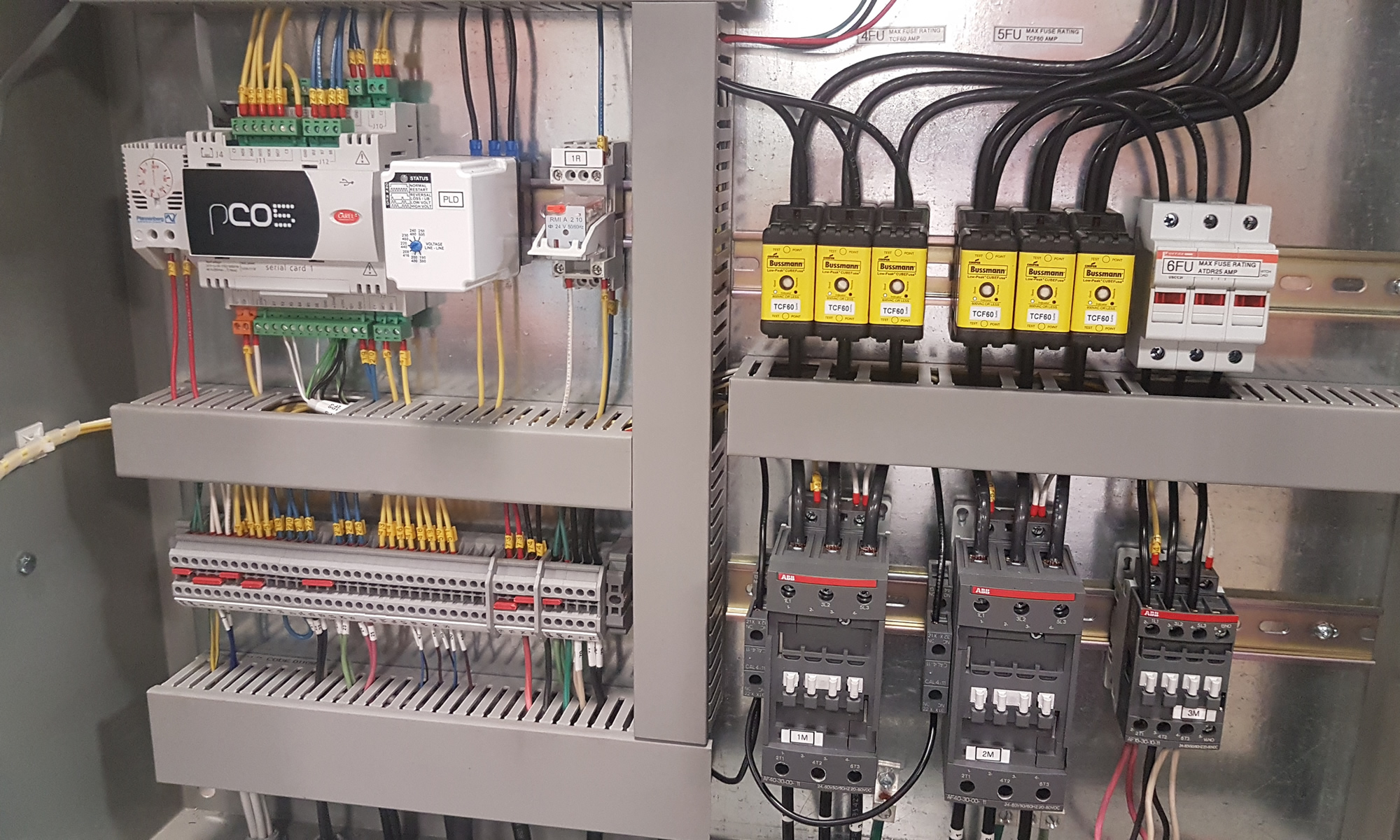

Chiller & Remote Master Controllers

- Chiller controller senses and displays entering and leaving chilled water temperature, suction and discharge pressures of each compressor, suction temperature, discharge temperature.

- Displays flow switch status (flow – no flow) and compressor internal overload protection status.

- Each chiller has it own display to monitor its operating and fault conditions.

- Our chiller controller operating with our system remote master can control from 2 to 12 chillers staging up to 24 compressors.

- Stages the chillers on leaving chilled water temperature but can be field changed to entering water.

- It lead lags the compressor on a first in – first out basis with field set time from 6 to 24 hours if one compressor leads the others it is held off line to further equalize the compressor run-time.

- Prevents short-cycling of compressors by setting the minimum on-time and minimum off-time.

- Stages compressors on at start-up to reduce in-rush current.

- The Remote Master default screen displays the number of compressors operating with an icon for each compressor (an outline when off, solid when operation), entering and leaving chiller water temperature.

- Allows you to remote monitor the operation of the chiller and its fault conditions.

- Sets off an alarm and keeps track of 20 fault conditions enabling easy repair of the chiller.

- Remote monitoring by BMS with either BACnet IP, BACnet MS/TP, Modbus and Lonworks.

- Allows remote monitoring over the Internet.